Difference between revisions of "12""

| Line 4: | Line 4: | ||

[[File:Rolling.gif|thumb|right|250px|Rolling]] | [[File:Rolling.gif|thumb|right|250px|Rolling]] | ||

[[File:Cross rolling HTML.jpg|thumb|right|250px|Cross rolling]] | [[File:Cross rolling HTML.jpg|thumb|right|250px|Cross rolling]] | ||

| − | |||

| − | |||

==B20 production (Formula 602, M.E. 602’s):== | ==B20 production (Formula 602, M.E. 602’s):== | ||

| − | + | Paiste does not have a foundry, they have traditionally used outside suppliers to provide their alloys with the first few production stages completed.<br> | |

| − | + | For B20 alloy they are delivered to Paiste as circular “blanks”.<br> | |

| − | + | *The B20 “blanks” were originally supplied by Swissmetal from about 1947 to 1994.<br> | |

| − | + | *The Formula 602 and Sound creation lines were discontinued because Swissmetal stopped making B20 blanks, it’s assumed it wasn’t cost effective for them at that point as Paiste would have been a small customer. | |

| − | + | *A German foundry/mill now supplies the B20 blanks for the “classic 602’s” and "modern essentials 602’s".<br> | |

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| + | There are advantages to using industrial foundries and mills: Production is on a much larger scale, they can produce several hundred blanks from one batch of alloy, the foundry also has the ability to do metallurgical analysis to ensure the alloy has the correct mix of components.<br> | ||

| + | The production process at the foundry and mill: A cymbal “blank” of B20 bronze is produced by hot rolling [1] and “cross rolling” [2] it from a small, thick ingot, into a large circular piece of B20 bronze. (The “hot rolling process” [1] forms the crystalline structure within the cymbal that contributes to the more refined sound of Bell Bronze).<br> | ||

| + | After being rolled out to approximate size, the flat blanks are delivered to Paiste. They are then reheated, a bell is stamped and quenched in water for “annealing” [3].<br> | ||

| + | In terms of shape at this stage, they are a raw, unworked cymbal blank, the cymbal looks like a giant bronze potato chip covered in oven crust.<br> | ||

| + | After this process, the cymbal is cleaned of the scale, a hole is punched in the bell and the hammering process begins.<br> | ||

| + | '''Hammering:''' A pneumatic hammer is operated manually by the cymbal-smith.<br> | ||

| + | He wears a mount on his left knee that holds the cymbal, he uses his thigh to move the cymbal in and out from the hammer to position the blows, with his right foot he controls the power of the hammer blows, with his hands he rotates the cymbal to evenly distribute the hammer marks. Paiste has been using this technique and same machines since at least the early 50’s.<br> | ||

| + | The next step is fine tuning: a different cymbal-smith now hammers the cymbal by had to fine tune the shape and checks the bow with a ruler and on a steel flat table to make sure the edges are straight, he also checks the cymbal against a “master” for hammer pattern and shape of the bow.<br> | ||

| + | *Paiste is the only company out of the “big three” (Paiste, Zildjian and Sabian) that uses hammering to shape the curve or “bow” of the cymbal: Zildjian and Sabian use a 75 ton press to and STAMP their cymbals into shape (for A Zildjian and Sabian AA models)!<br> | ||

| + | '''Specification card:''' Each cymbal-smith has a “specification card” that travels with each model/size of cymbal, it tells him the exact weight, thickness and hammering pattern for that cymbal.<br> | ||

| + | '''Lathing:''' Lathing does two things: brings the cymbal down to the desired thickness and creates the lathing grooves witch refines the sound and defines the character of that cymbal line.<br> | ||

| + | The cymbal-smith checks the thickness of the cymbal with a micrometer during this process.<br> | ||

| + | '''Finishing:''' The edges are cleaned up and chamfered, a serial number is laser etched into the bottom. The cymbals then have their respective logo, model, size printed on them and a protective coating is applied (Paiste was the 1st. to do this with the 602 series in the 1960’s).<br> | ||

| + | '''Quality control:''' Each cymbal is tested against a “Klangmuster” (master cymbal) for consistency, if it does not pass the cymbal is rejected and melted down.<br> <br> | ||

| Line 42: | Line 34: | ||

==Twenty and Twenty Masters Collection production:== | ==Twenty and Twenty Masters Collection production:== | ||

| − | The | + | The original “Twenty” blanks were supplied from the Foundry of Murat Diril in Turkey along with pre-work (rolling and tempering) done to the cymbals before they were been shipped off to Switzerland for completion.<br> |

There were well publicized issues with the quality of the blanks and high rejection rate, so Turkish suppliers were changed before the current Twenty series started.<br> | There were well publicized issues with the quality of the blanks and high rejection rate, so Turkish suppliers were changed before the current Twenty series started.<br> | ||

| − | Paiste emphasizes that every crucial stage of the production is completed by hand, from the initial casting to the lathing and hammering.<br> | + | The blanks would arrive at Paiste in the same state as they do from their local suppliers. After the bells were pressed in, the process differs, most if not all the hammering is done by hand.<br> |

| + | “Paiste emphasizes that every crucial stage of the production is completed by hand, from the initial casting to the lathing and hammering.”<br><br> | ||

<gallery> | <gallery> | ||

| Line 57: | Line 50: | ||

File:Klangmusters MasterCymbals.jpg | File:Klangmusters MasterCymbals.jpg | ||

File:Thin ride.jpg | File:Thin ride.jpg | ||

| − | </gallery> | + | </gallery><br> |

| + | |||

==B15 (Paiste Signature Sound Alloy):== | ==B15 (Paiste Signature Sound Alloy):== | ||

| − | B15 just like B20, rolled in different directions. | + | Paiste's B15 (Signature Sound Alloy) blanks are supplied by the "Wieland works" in Vöhringen Germany. B15 just like B20, goes through the same processes: hot rolled and cross rolled in different directions.<br> |

| − | + | Once they arrive at Paiste, they would also have to heat the whole of the cymbal agine to press the in the bell like they do with the B20 alloy.<br> | |

| − | + | After this process, the blank is allowed to cool for 24 hours. As a result of this annealing, the material is now more pliable and tougher. | |

| − | + | '''Hammering:''' Same processes as B20.<br> | |

| − | + | '''Lathing:''' Same processes as B20 except Paiste developed a different shaped knife for a unique "flat groove" lathing pattern.<br> | |

| + | '''Finishing:''' Same processes as B20.<br> | ||

| + | '''Quality control:''' Same processes as B20.<br> | ||

| − | + | '''Early 90's factory tour with Nicko McBrain''' [https://youtu.be/aLs4cNCSMBI B15 Signature cymbal production tour]<br><br> | |

| − | [https://youtu.be/aLs4cNCSMBI B15 Signature cymbal production tour] | ||

<gallery> | <gallery> | ||

| Line 81: | Line 76: | ||

File:Prod10.jpg | File:Prod10.jpg | ||

File:70s lathing.jpg | File:70s lathing.jpg | ||

| − | </gallery> | + | </gallery><br> |

| + | |||

| + | |||

==B8 (2002 Alloy):== | ==B8 (2002 Alloy):== | ||

The mill/supplier (Swissmetal) most likely pours out long square ingot bars (the casting part), it is then cooled and "cold rolled" [1] multiple times (see link below) into long thin sheets (hence Zildjian's term "sheet bronze"), they then cut circular discs out of the sheet and deliver them to Paiste. Cold rolling operation actually increases the strength via "strain hardening" up to 20%, it also improves the surface finish and holds tighter tolerances. | The mill/supplier (Swissmetal) most likely pours out long square ingot bars (the casting part), it is then cooled and "cold rolled" [1] multiple times (see link below) into long thin sheets (hence Zildjian's term "sheet bronze"), they then cut circular discs out of the sheet and deliver them to Paiste. Cold rolling operation actually increases the strength via "strain hardening" up to 20%, it also improves the surface finish and holds tighter tolerances. | ||

| − | I've seen the video of them heating just the center of a B8 cymbal to press the cup in. | + | I've seen the video of them heating just the center of a B8 cymbal to press the cup in.<br><br> |

| + | |||

<gallery> | <gallery> | ||

File:B8 Center Heating 2.jpg | File:B8 Center Heating 2.jpg | ||

| Line 97: | Line 95: | ||

File:Applying Final Coating.jpg | File:Applying Final Coating.jpg | ||

File:Final Sound Control.jpg|Final testing | File:Final Sound Control.jpg|Final testing | ||

| − | </gallery> | + | </gallery><br> |

| − | |||

== Paiste, Zildjian and Sabian's production differences== | == Paiste, Zildjian and Sabian's production differences== | ||

| Line 105: | Line 102: | ||

The Rotary Hammer is an example of automation circa early 1990s. Zildjian were experimenting with pressing into shape rather than hammering for bow shape starting in the very late 60s (Robert Zildjian in Canada, later moved to the USA operation). The full process using the Rotary Hammer went: rotary hammering machine, then pressed into shape, then some additional hammering done by a person holding a cymbal under a mechanical hammer. | The Rotary Hammer is an example of automation circa early 1990s. Zildjian were experimenting with pressing into shape rather than hammering for bow shape starting in the very late 60s (Robert Zildjian in Canada, later moved to the USA operation). The full process using the Rotary Hammer went: rotary hammering machine, then pressed into shape, then some additional hammering done by a person holding a cymbal under a mechanical hammer. | ||

Paiste kept hamming for shape right through to the present. According to my cymbal making friends how the shape of the bow is formed makes a crucial difference to the sound. Paiste was doing mechanization, Zildjian went for automation. 602s sounded the same in 1960 as they did in 1970 as they did in 1980 as they do today. | Paiste kept hamming for shape right through to the present. According to my cymbal making friends how the shape of the bow is formed makes a crucial difference to the sound. Paiste was doing mechanization, Zildjian went for automation. 602s sounded the same in 1960 as they did in 1970 as they did in 1980 as they do today. | ||

| − | Zildjians changed sound due to changes in production technology. | + | Zildjians changed sound due to changes in production technology.<br><br> |

<gallery> | <gallery> | ||

| Line 113: | Line 110: | ||

File:Zildjian-cookie-cutter-ad.jpg | File:Zildjian-cookie-cutter-ad.jpg | ||

File:Zildjian-sheet-metal-ad.jpg | File:Zildjian-sheet-metal-ad.jpg | ||

| − | </gallery> | + | </gallery><br> |

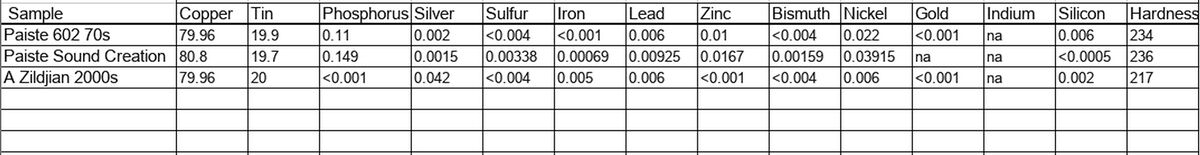

===B20 metallurgical analysis, Paiste vs. Zildjian=== | ===B20 metallurgical analysis, Paiste vs. Zildjian=== | ||

[[File:Metalurgical analisys.jpg|1200px]] | [[File:Metalurgical analisys.jpg|1200px]] | ||

| + | |||

==Notes and references== | ==Notes and references== | ||

Revision as of 20:40, 30 October 2021

B20 production (Formula 602, M.E. 602’s):

Paiste does not have a foundry, they have traditionally used outside suppliers to provide their alloys with the first few production stages completed.

For B20 alloy they are delivered to Paiste as circular “blanks”.

- The B20 “blanks” were originally supplied by Swissmetal from about 1947 to 1994.

- The Formula 602 and Sound creation lines were discontinued because Swissmetal stopped making B20 blanks, it’s assumed it wasn’t cost effective for them at that point as Paiste would have been a small customer.

- A German foundry/mill now supplies the B20 blanks for the “classic 602’s” and "modern essentials 602’s".

There are advantages to using industrial foundries and mills: Production is on a much larger scale, they can produce several hundred blanks from one batch of alloy, the foundry also has the ability to do metallurgical analysis to ensure the alloy has the correct mix of components.

The production process at the foundry and mill: A cymbal “blank” of B20 bronze is produced by hot rolling [1] and “cross rolling” [2] it from a small, thick ingot, into a large circular piece of B20 bronze. (The “hot rolling process” [1] forms the crystalline structure within the cymbal that contributes to the more refined sound of Bell Bronze).

After being rolled out to approximate size, the flat blanks are delivered to Paiste. They are then reheated, a bell is stamped and quenched in water for “annealing” [3].

In terms of shape at this stage, they are a raw, unworked cymbal blank, the cymbal looks like a giant bronze potato chip covered in oven crust.

After this process, the cymbal is cleaned of the scale, a hole is punched in the bell and the hammering process begins.

Hammering: A pneumatic hammer is operated manually by the cymbal-smith.

He wears a mount on his left knee that holds the cymbal, he uses his thigh to move the cymbal in and out from the hammer to position the blows, with his right foot he controls the power of the hammer blows, with his hands he rotates the cymbal to evenly distribute the hammer marks. Paiste has been using this technique and same machines since at least the early 50’s.

The next step is fine tuning: a different cymbal-smith now hammers the cymbal by had to fine tune the shape and checks the bow with a ruler and on a steel flat table to make sure the edges are straight, he also checks the cymbal against a “master” for hammer pattern and shape of the bow.

- Paiste is the only company out of the “big three” (Paiste, Zildjian and Sabian) that uses hammering to shape the curve or “bow” of the cymbal: Zildjian and Sabian use a 75 ton press to and STAMP their cymbals into shape (for A Zildjian and Sabian AA models)!

Specification card: Each cymbal-smith has a “specification card” that travels with each model/size of cymbal, it tells him the exact weight, thickness and hammering pattern for that cymbal.

Lathing: Lathing does two things: brings the cymbal down to the desired thickness and creates the lathing grooves witch refines the sound and defines the character of that cymbal line.

The cymbal-smith checks the thickness of the cymbal with a micrometer during this process.

Finishing: The edges are cleaned up and chamfered, a serial number is laser etched into the bottom. The cymbals then have their respective logo, model, size printed on them and a protective coating is applied (Paiste was the 1st. to do this with the 602 series in the 1960’s).

Quality control: Each cymbal is tested against a “Klangmuster” (master cymbal) for consistency, if it does not pass the cymbal is rejected and melted down.

Twenty and Twenty Masters Collection production:

The original “Twenty” blanks were supplied from the Foundry of Murat Diril in Turkey along with pre-work (rolling and tempering) done to the cymbals before they were been shipped off to Switzerland for completion.

There were well publicized issues with the quality of the blanks and high rejection rate, so Turkish suppliers were changed before the current Twenty series started.

The blanks would arrive at Paiste in the same state as they do from their local suppliers. After the bells were pressed in, the process differs, most if not all the hammering is done by hand.

“Paiste emphasizes that every crucial stage of the production is completed by hand, from the initial casting to the lathing and hammering.”

B15 (Paiste Signature Sound Alloy):

Paiste's B15 (Signature Sound Alloy) blanks are supplied by the "Wieland works" in Vöhringen Germany. B15 just like B20, goes through the same processes: hot rolled and cross rolled in different directions.

Once they arrive at Paiste, they would also have to heat the whole of the cymbal agine to press the in the bell like they do with the B20 alloy.

After this process, the blank is allowed to cool for 24 hours. As a result of this annealing, the material is now more pliable and tougher.

Hammering: Same processes as B20.

Lathing: Same processes as B20 except Paiste developed a different shaped knife for a unique "flat groove" lathing pattern.

Finishing: Same processes as B20.

Quality control: Same processes as B20.

Early 90's factory tour with Nicko McBrain B15 Signature cymbal production tour

B8 (2002 Alloy):

The mill/supplier (Swissmetal) most likely pours out long square ingot bars (the casting part), it is then cooled and "cold rolled" [1] multiple times (see link below) into long thin sheets (hence Zildjian's term "sheet bronze"), they then cut circular discs out of the sheet and deliver them to Paiste. Cold rolling operation actually increases the strength via "strain hardening" up to 20%, it also improves the surface finish and holds tighter tolerances.

I've seen the video of them heating just the center of a B8 cymbal to press the cup in.

Paiste, Zildjian and Sabian's production differences

Paiste tempering: The temperatures are considerably lower than at Zildjian or Sabian: when the hot cymbal hits the cold liquid all you hear is a modest hiss, instead of the frightening shriek at the other companies.

You also start to see what I mean by Paiste being more conservative. They kept on doing things the late 1950s way while Zildjian kept doing more mechanization and later automation.

The Rotary Hammer is an example of automation circa early 1990s. Zildjian were experimenting with pressing into shape rather than hammering for bow shape starting in the very late 60s (Robert Zildjian in Canada, later moved to the USA operation). The full process using the Rotary Hammer went: rotary hammering machine, then pressed into shape, then some additional hammering done by a person holding a cymbal under a mechanical hammer.

Paiste kept hamming for shape right through to the present. According to my cymbal making friends how the shape of the bow is formed makes a crucial difference to the sound. Paiste was doing mechanization, Zildjian went for automation. 602s sounded the same in 1960 as they did in 1970 as they did in 1980 as they do today.

Zildjians changed sound due to changes in production technology.

B20 metallurgical analysis, Paiste vs. Zildjian

Notes and references

Rolling:

[1] Rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property. The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled. If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling. If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling.

Cross rolling:

[2] Cross rolling is a way of reducing the directional dependency of different properties of the rolled plate. Cross rolling is normally done by changing the rolling direction by 90° about the normal direction. Changes in residual stress distribution cross rolling leads to rolled product of comparatively uniform mechanical properties in all directions

Annealing

[3] Annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness, making it more workable. It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooled. Bronze can be either cooled slowly in air, or quickly by quenching in water. In this fashion, the metal is softened and prepared for further work such as hammering, shaping, stamping, or forming.

Tempering

[4] Tempering is a process of heat treating, it is done to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered at much higher temperatures.