Difference between revisions of "Paiste's cymbal production process"

m |

|||

| (25 intermediate revisions by the same user not shown) | |||

| Line 1: | Line 1: | ||

__NOEDITSECTION__ | __NOEDITSECTION__ | ||

| − | |||

<div style="float:right">__TOC__</div> | <div style="float:right">__TOC__</div> | ||

| − | [[File: | + | [[File:Recrystallization-during-hot-rolling.jpg|thumb|right|350px|hot rolling showing change in crystalline structure]] |

| − | [[File: | + | [[File:Hot-rolling-vs-cold-rolling.jpg|thumb|right|350px|Hot-rolling-vs-cold-rolling]] |

==B20 production (Formula 602, Modern essentials 602’s)== | ==B20 production (Formula 602, Modern essentials 602’s)== | ||

''<b>The processes described below apply to Paiste's current "top line" cymbals and some of their "midline" cymbals.</b>''<br> | ''<b>The processes described below apply to Paiste's current "top line" cymbals and some of their "midline" cymbals.</b>''<br> | ||

| − | |||

Paiste does not have a foundry, they have traditionally used an outside supplier to provide their alloys with the first production stage completed.<br> | Paiste does not have a foundry, they have traditionally used an outside supplier to provide their alloys with the first production stage completed.<br> | ||

For the B20 alloy they are delivered to Paiste as circular “blanks”.<br> | For the B20 alloy they are delivered to Paiste as circular “blanks”.<br> | ||

| − | *The B20 “blanks” were | + | *The B20 “blanks” were supplied by [https://de.wikipedia.org/wiki/Swissmetal '''Swissmetal'''] from 1957 to 1994, they were originally called "Metallwerke Dornach AG".<br> |

| − | *The Formula 602 and Sound creation lines were discontinued | + | *Metallwerke Dornach supplied B20 alloy for the Swiss mint, Swiss coins were made out of B20 bronze.<br> |

| − | *" | + | *Robert Paiste founded the Swiss factory across the lake from where Metallwerke Dornach was located by accident (Paiste had not used B20 alloy up to that point), little did he know they were the only foundry and mill that produced B20 bronze in all of Switzerland and possibly all of western Europe!<br> |

| + | *Robert Paiste initially worked with Swissmetal and developed a process of rolling B20 thin enough for B20 cymbal production: [https://youtu.be/KH2TPkhL0Ik?si=fTiEIgBqsqbBE5d9 <b>Fritz Steger's explanation of the sourcing and development of Paiste's B20 alloy</b>].<br> | ||

| + | *The Formula 602 and Sound creation lines were discontinued around 1994 (or earlier) because Swissmetal stopped making B20 blanks, it is understood that Swissmetal went through substantial financial difficulties during this time, it’s assumed it wasn’t cost effective for them at that point as Paiste would have been a small customer. | ||

| + | *"Weilandworks" in Vöhringen Germany now supply all of Paiste's alloys but specifically; they supply the B20 blanks for the “classic 602’s” and "modern essentials 602’s".<br> | ||

| − | There are advantages to using industrial foundries and mills: Production is on a much larger scale, they can produce several hundred blanks from one batch of alloy, the foundry also has the ability to | + | There are advantages to using industrial foundries and mills: Production is on a much larger scale, they can produce several hundred blanks from one batch of alloy, the foundry also has the ability to keep incredibly tight tolerances on temperature control and mixing along with metallurgical analysis to ensure the alloy has the correct characteristics for reliable consistent cymbals making.<br> |

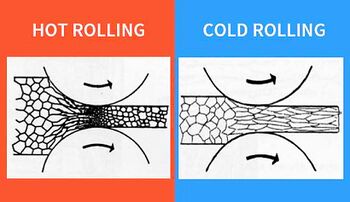

| − | '''The production process at the foundry and mill:''' | + | '''The production process at the foundry and mill:''' B20 bronze is produced by hot rolling [1] in multiple stages from a thick plank/ingot into a thin sheet slightly thicker than the heaviest cymbal thickness required (Wieland works may use the '''continuous casting''' process for B20 alloys, see below).<br> |

| − | (The “hot rolling process” [1] forms the crystalline structure | + | (The “hot rolling process” [1] forms the desired and stable crystalline structure that contributes to the more refined sound of Bell Bronze). B20 is a "two-phase" alloy: meaning some of the tin is not dissolved in the copper grains but exists between them, in its natural state it is very brittle, there is a large amount of work done to the material (heating/recrystallisation) to get it conditioned so it can be hammered and lathed without cracking.<br> |

| − | After being rolled out to approximate size and thickness, | + | After being rolled out to approximate size and thickness, flat blanks are cut to the specified size and delivered to Paiste. They are then reheated to "anneal" them (soften) and then quenched in water, a bell is then stamped in the blank.<br> |

In terms of shape at this stage, they are a raw, unworked cymbal blank, the cymbal looks like a giant bronze potato chip covered in oven crust.<br> | In terms of shape at this stage, they are a raw, unworked cymbal blank, the cymbal looks like a giant bronze potato chip covered in oven crust.<br> | ||

After this process, the cymbal is cleaned of the scale, a hole is punched in the bell and the hammering process begins.<br> | After this process, the cymbal is cleaned of the scale, a hole is punched in the bell and the hammering process begins.<br> | ||

| − | '''Hammering:''' Paiste has used the same production processes from at least the mid 50's (they got | + | '''Hammering:''' Paiste has used the same production processes from at least the mid 50's or earlier (they got their first hammering machine in 1952) to the present on all thier top of the line Swiss and German produced cymbals.<br> |

An electro pneumatic hammer is operated manually by the cymbal-smith, he wears a mount with a spindle on his left knee that holds the cymbal, he uses his thigh to move the cymbal in and out from the hammer to position the blows, with his right foot he controls the power/depth of the hammer blows, with his hands he rotates the cymbal to evenly distribute the hammer marks.<br> | An electro pneumatic hammer is operated manually by the cymbal-smith, he wears a mount with a spindle on his left knee that holds the cymbal, he uses his thigh to move the cymbal in and out from the hammer to position the blows, with his right foot he controls the power/depth of the hammer blows, with his hands he rotates the cymbal to evenly distribute the hammer marks.<br> | ||

| − | Paiste has been using this technique and the same type of machines since at least the | + | Paiste has been using this technique and the same type of machines since at least the mid 50’s or earlier.<br> |

| − | The next step is fine tuning: a different cymbal-smith now hammers the cymbal by | + | The next step is fine tuning: a different cymbal-smith now hammers the cymbal by hand to fine tune the shape and checks the bow with a ruler and on a steel flat table to make sure the edges are straight, he also checks the cymbal against a “master” for hammer pattern and shape of the bow.<br> |

| − | *Paiste is the only company out of the “big | + | |

| + | *Paiste is the only company out of the “big four” (Paiste, Zildjian, Sabian and Meinl) that uses manual machine hammering to shape the curve or “bow” of all of their top line cymbals. they have used the same process since 1952. | ||

| + | *Meinl uses a computer controlled hammering machine to shape one line of their cymbals otherwise the majority are "spin formed" into shape (the exception are Meinl's Byzance Turkish made cymbals), all of their cymbal production is completely computer controlled and automated. | ||

| + | *Zildjian and Sabian use a 75 ton press to '''STAMP''' most of their cymbals to create the "bow" or shape of the cymbal (there are some exceptions).<br> | ||

| + | |||

'''Specification card:''' Each cymbal-smith has a “specification card” that travels with each model/size of cymbal, it tells him the exact weight, thickness and hammering pattern for that cymbal.<br> | '''Specification card:''' Each cymbal-smith has a “specification card” that travels with each model/size of cymbal, it tells him the exact weight, thickness and hammering pattern for that cymbal.<br> | ||

| Line 34: | Line 39: | ||

'''Finishing:''' The edges are cleaned up and chamfered, a serial number is laser etched into the bottom. The cymbals then have their respective logo, model, size printed on them and a protective coating is applied (Paiste was the 1st. to do this with the 602 series in the 1960’s).<br> | '''Finishing:''' The edges are cleaned up and chamfered, a serial number is laser etched into the bottom. The cymbals then have their respective logo, model, size printed on them and a protective coating is applied (Paiste was the 1st. to do this with the 602 series in the 1960’s).<br> | ||

| − | '''Quality control:''' Each cymbal is tested against a finished “Klangmuster” (master cymbal) for consistency, if it does not pass the cymbal is rejected and | + | '''Quality control:''' Each cymbal is tested against a finished “Klangmuster” (master cymbal) for consistency, if it does not pass the cymbal is rejected and scraped.<br> |

<gallery> | <gallery> | ||

| − | File:B20 reheating blanks.jpg|1960's Reheating 602 blanks | + | File:B20 reheating blanks.jpg|1960's Reheating/annealing 602 blanks so they can press in the bell |

| − | File:60s hammering.jpg|1960's | + | File:60s hammering.jpg|1960's manual machine hammering, same as today |

File:60s hammering (2).jpg|1960's Hand hammering, fine tuning | File:60s hammering (2).jpg|1960's Hand hammering, fine tuning | ||

| − | File:1963 hammering.jpg|1960's Hand hammering | + | File:1963 hammering.jpg|1960's Hand hammering |

| + | File:60s lathing.jpg|1960's lathing , same as today | ||

File:1979 catalog 1.jpg|Sorting 602 blanks, 2002 hammering, stamping bell | File:1979 catalog 1.jpg|Sorting 602 blanks, 2002 hammering, stamping bell | ||

File:Checking flatness.jpg|Checking flatness | File:Checking flatness.jpg|Checking flatness | ||

| − | File: | + | File:Swissmetal 2.jpg|Swissmetal blank before it's turned into a bell |

| − | |||

File:Klangmusters MasterCymbals.jpg|Testing room with "Klangmusters" | File:Klangmusters MasterCymbals.jpg|Testing room with "Klangmusters" | ||

File:Thin ride.jpg|1960's Preparing for shipment | File:Thin ride.jpg|1960's Preparing for shipment | ||

</gallery> | </gallery> | ||

| − | ===Twenty and Twenty Masters Collection production | + | |

| + | [https://youtu.be/ePPjzMeH830?si=aiiWyX6hRsFM4ua_ Rhythm Magazine Paiste factory tour B8 production] | ||

| + | |||

| + | |||

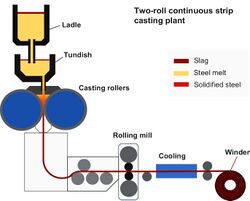

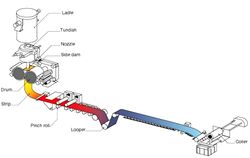

| + | ==Continuous strip or band casting process== | ||

| + | [[File:2 roll continuous.jpg|thumb|right|250px|]] | ||

| + | [[File:Band casting.jpg|thumb|right|250px|]] | ||

| + | Weilandworks uses the continuous strip or band casting process for producing B20 B15 and possibly B20 alloys it supplies to Paiste.<br> | ||

| + | |||

| + | '''What is the difference between casting and continuous casting?'''<br> | ||

| + | |||

| + | Basically, in Ingot casting, individual molds are filled with molten steel to produce bronze ingots whereas in Continuous casting, the molten alloy is solidified into a "semi finished" billet, or slab for subsequent hot or cold rolling in the finishing mills.<br> | ||

| + | |||

| + | '''What is the advantage of continuous casting?'''<br> | ||

| + | |||

| + | Continuous casting helps improve the quality of metal products by reducing impurities and variations in size and shape. This results in consistent and higher-quality products with fewer defects.<br> | ||

| + | The continuous casting method offers a superior surface finish and virtually eliminates internal porosity and centerline shrinkage.<br> | ||

| + | The majority of bronze castings are produced through the sand casting process. However, there are clear deficiencies in the this choice when compared to continuous casting.<br> | ||

| + | |||

| + | '''What are the disadvantages of continuous casting?''' | ||

| + | |||

| + | It isn't economical to use this method with special metal alloys in small quantities<br> | ||

| + | In conclusion, continuous casting offers several advantages, including high productivity, consistent quality, and cost-effectiveness.<br><br> | ||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | |||

| + | ==Twenty and Twenty Masters Collection production== | ||

The original “Twenty” blanks were supplied from the Foundry of Murat Diril in Turkey along with pre-work done to the cymbals before they were shipped off to Switzerland for completion.<br> | The original “Twenty” blanks were supplied from the Foundry of Murat Diril in Turkey along with pre-work done to the cymbals before they were shipped off to Switzerland for completion.<br> | ||

| − | There were well publicized issues with the quality of the blanks and high rejection rate, so Turkish suppliers | + | There were well publicized issues with the quality of the blanks and high rejection rate, so Turkish suppliers were changed before the current Twenty Custom/Twenty Masters series started.<br> |

| − | The process with their new supplier according to Paiste | + | The process with their new supplier according to Paiste: "They begin by being hammered and shaped in Turkey, then we send them to Switzerland where we do the finish hammering and lathing and all the other work that makes it a Paiste cymbal." <br> |

All the hammering is done by hand according to Erik Paiste: “Paiste emphasizes that every crucial stage of the production is completed by hand, from the initial casting to the lathing and hammering.”<br> | All the hammering is done by hand according to Erik Paiste: “Paiste emphasizes that every crucial stage of the production is completed by hand, from the initial casting to the lathing and hammering.”<br> | ||

| − | + | ||

| − | + | ||

| − | |||

| − | |||

==B15 (Paiste Signature Sound Alloy)== | ==B15 (Paiste Signature Sound Alloy)== | ||

[[File:Paiste demo.jpg|thumb|right|250px|]] | [[File:Paiste demo.jpg|thumb|right|250px|]] | ||

| − | Paiste's B15 (Signature Sound Alloy) blanks are supplied by the "Wieland works" in Vöhringen Germany.<br> | + | Paiste's B15 (Signature Sound Alloy) blanks are supplied by the "Wieland works" in Vöhringen Germany. They were initially supplied by "Kovohutí Příbram" from the Czech republic but they had serious issues with cracking, once the production moved to Wieland, the issue was resolved. [https://youtu.be/senTufOv2n4?si=cA11bOQev74yQqoq Fritz Steger describes the early production issues with B15]<br> |

B15 like B20, goes through some of the same processes: initially hot rolled to about 60mm thickness then the last stage is cold rolled. Also, it is not tempered [4] like traditional B20 cymbals but is annealed [3].<br> | B15 like B20, goes through some of the same processes: initially hot rolled to about 60mm thickness then the last stage is cold rolled. Also, it is not tempered [4] like traditional B20 cymbals but is annealed [3].<br> | ||

Using this alloy allows for greater consistency between blanks compared to traditional B20 cymbal alloy, and is more inline with Paiste's B8 production methods.<br> | Using this alloy allows for greater consistency between blanks compared to traditional B20 cymbal alloy, and is more inline with Paiste's B8 production methods.<br> | ||

| Line 72: | Line 107: | ||

'''Quality control:''' Same processes as B20.<br> | '''Quality control:''' Same processes as B20.<br> | ||

| − | '''Early 90's factory tour with Nicko McBrain''' [https://youtu.be/ | + | '''Early 90's factory tour with Nicko McBrain''' [https://youtu.be/6EL3AtOyJs0 B15 Signature cymbal production tour]<br> |

<gallery> | <gallery> | ||

| Line 88: | Line 123: | ||

"<i>The material or special alloy for the inventive cymbal 1 can be processed, by way of example and not limitation, as hereinafter disclosed:<br> | "<i>The material or special alloy for the inventive cymbal 1 can be processed, by way of example and not limitation, as hereinafter disclosed:<br> | ||

An alloy containing, for example, 14.7 percent by weight tin, 0.08 percent by weight phosphorus and 85.22 percent by weight copper is initially melted in an induction melting furnace. | An alloy containing, for example, 14.7 percent by weight tin, 0.08 percent by weight phosphorus and 85.22 percent by weight copper is initially melted in an induction melting furnace. | ||

| − | The melt is delivered at a temperature of 1000° C. to 1200° C. into a heat retention or holding furnace of a strip or band casting installation. A strip or band is cast.<br> | + | The melt is delivered at a temperature of 1000° C. to 1200° C. into a heat retention or holding furnace of '''a strip or band casting installation. A strip or band is cast'''.<br> |

The cast strip or band has, for example, a width of 670 mm and a thickness of 18 mm. This strip or band cannot be coiled and is therefore cut into plates of approximately 3 to 4 meters length.<br> | The cast strip or band has, for example, a width of 670 mm and a thickness of 18 mm. This strip or band cannot be coiled and is therefore cut into plates of approximately 3 to 4 meters length.<br> | ||

Such plates are now homogenized at 600° C. to 700° C. during about 10 to 25 hours.<br> | Such plates are now homogenized at 600° C. to 700° C. during about 10 to 25 hours.<br> | ||

| Line 100: | Line 135: | ||

==B8 (2002 Alloy)== | ==B8 (2002 Alloy)== | ||

| − | [[File: | + | [[File:Hot-rolling-vs-cold-rolling.jpg|thumb|right|350px|Hot-rolling-vs-cold-rolling]] |

B8 alloy is very different compared to B20: it's softer, much more malleable, easier to work and doesn't require multiple heating stages before each rolling cycle to prepare it for hammering.<br> | B8 alloy is very different compared to B20: it's softer, much more malleable, easier to work and doesn't require multiple heating stages before each rolling cycle to prepare it for hammering.<br> | ||

Paiste's B8 alloy blanks originally came from Metallwerke Dornach AG, aka: Swissmetal, the same source as their B20, they are now supplied by the "Wieland works".<br> | Paiste's B8 alloy blanks originally came from Metallwerke Dornach AG, aka: Swissmetal, the same source as their B20, they are now supplied by the "Wieland works".<br> | ||

| Line 107: | Line 142: | ||

The mill then cuts circular blanks out of the sheets and delivers them to Paiste. Once they arrive at Paiste, they would heat the center of the cymbal in order to press the in the bell. <br> | The mill then cuts circular blanks out of the sheets and delivers them to Paiste. Once they arrive at Paiste, they would heat the center of the cymbal in order to press the in the bell. <br> | ||

For the china type cymbals they "form or spin" the shape of the bell into the unique cylindrical shape.<br> | For the china type cymbals they "form or spin" the shape of the bell into the unique cylindrical shape.<br> | ||

| − | |||

'''Hammering:''' Same processes as B20 & B15.<br> | '''Hammering:''' Same processes as B20 & B15.<br> | ||

'''Lathing:''' Same processes as B20 & B15.<br> | '''Lathing:''' Same processes as B20 & B15.<br> | ||

'''Finishing:''' Same processes as B20 & B15.<br> | '''Finishing:''' Same processes as B20 & B15.<br> | ||

'''Quality control:''' Same processes as B20 & B15.<br> | '''Quality control:''' Same processes as B20 & B15.<br> | ||

| − | + | [https://youtu.be/3Cl1hs7O_Hg?t=68 '''B8 production tour with Dave Lombardo''']<br> | |

| − | [https://youtu.be/3Cl1hs7O_Hg?t=68 B8 production tour with Dave Lombardo]<br> | ||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

| − | |||

<gallery> | <gallery> | ||

| − | |||

File:B8 Center Heating 2.jpg|B8 Center Heating | File:B8 Center Heating 2.jpg|B8 Center Heating | ||

File:Bell Pressed.jpg|B8 Bell Pressed | File:Bell Pressed.jpg|B8 Bell Pressed | ||

| Line 137: | Line 160: | ||

File:Applying Final Coating.jpg|Applying Final Coating | File:Applying Final Coating.jpg|Applying Final Coating | ||

File:Cymbal Production Klangmuster.jpg|"Klangmuster" | File:Cymbal Production Klangmuster.jpg|"Klangmuster" | ||

| − | </gallery | + | </gallery> |

== Swiss and German factories == | == Swiss and German factories == | ||

[[File:German 602.jpg|thumb|right|350px|Early 602 finished at the German factory]] | [[File:German 602.jpg|thumb|right|350px|Early 602 finished at the German factory]] | ||

| − | The German factory was the 1st, to start production around 1947, the Swiss factory | + | The German factory was the 1st, to start production around 1947/48, in 1957 Robert Paiste moved to Nottwil Switzerland by himself and setup the Swiss factory. The German factory is the sole producer of gongs, and has been since opening.<br> |

Both factories made both levels of product except the German factory didn't make B20 cymbals or Giant beats.<br> | Both factories made both levels of product except the German factory didn't make B20 cymbals or Giant beats.<br> | ||

Many 2002's were made in 70s and 80s at the German factory and the German factory also "finished" a small number of 602s during the preserial days (** see below). <br> | Many 2002's were made in 70s and 80s at the German factory and the German factory also "finished" a small number of 602s during the preserial days (** see below). <br> | ||

| − | The German factory made practically all the vintage Paiste lines: 2002 | + | The German factory made practically all the vintage Paiste lines: 2002 (up to 1986), 2000, 1000, 400, 200, Stambul '65, Stambul, 404, 505, Ludwig cymbals, Dixies, Supers, Stanoples, Zilkos, etc.<br> |

| + | They still make all the lower lines and "OEM" cymbals, see video link below.<br> | ||

There is a notion among some that the Swiss versions are better quality... they are not, some German versions are usually a little heavier and a little darker sounding. <br> | There is a notion among some that the Swiss versions are better quality... they are not, some German versions are usually a little heavier and a little darker sounding. <br> | ||

People are less familiar with German Paistes because the Swiss factory did most of the exporting, so the U.S. didn't get German 2002's or 404's or 505's.<br> | People are less familiar with German Paistes because the Swiss factory did most of the exporting, so the U.S. didn't get German 2002's or 404's or 505's.<br> | ||

| Line 155: | Line 179: | ||

Kind regards, Customer Service Department<br> | Kind regards, Customer Service Department<br> | ||

Paiste Switzerland"</i><br><br> | Paiste Switzerland"</i><br><br> | ||

| + | |||

| + | == A word about "cast" vs. "sheet bronze" cymbals: == | ||

| + | Zildjian and Sabian (mainly Zildjian) have for many years used these terms in their marketing and advertising, they've alluded to in the past about B8 (and possibly B20 602's as well) "sheet bronze", "cookie cutter" cymbals being "stamped and formed" and inferior in both sound and quality (see advertisements below).<br> | ||

| + | There are many misconceptions created by these statements: both alloys are "cast" at some point, B20 is delivered to Zildjian and Sabian as cast ingots from their in house foundry, they then heat and "hot roll/cross roll"<br> (see link below) the ingots to the general size and thickness, they must be reheated after every rolling stage (Paiste's B20 supplier uses this same process), they are also tempered/annealed and quenched (see link below) during this time and before being stamped into shape (for most of thier lines) and lathing.<br> | ||

| + | The reason for this is the B20 alloy is very brittle (the tin doesn't completely mix with the copper at a microscopic level, in the B8 alloy it does), there is a large amount of work done (heating, reheating quenching) to the material just to get it conditioned so it can be hammered and lathed without cracking!<br> | ||

| + | The B8 alloy is very different, it's much more malleable and workable, the foundry (Weilandworks) most likely pours out long square ingot bars (the casting part), it is then cooled and "cold rolled" multiple times (see link below) into long thin sheets (hence Zildjian's term "sheet bronze"), they then cut circular discs out of the sheet and deliver them to Paiste. Cold rolling operation actually increases the strength via "strain hardening" up to 20%, it also improves the surface finish and holds tighter tolerances.<br> | ||

| + | |||

| + | To summarize: | ||

| + | B8 production techniques and the alloy itself does not make it inferior for cymbal making, it's just different, it's inherently easier to work with, its' more consistent batch to batch and doesn't suffer the higher rejection/defect rate that B20 does, this means B8 cymbals are less expensive to produce, not inferior quality. Paiste figured this out in the early/mid 60's and has mastered the production techniques and sound qualities of this alloy.<br> | ||

| + | It's also telling that neither Zildjian or Sabian have attempted to produce a top level B8 cymbal (Meinl has for decades), could it be that Zildjian and Sabian can't or don't want to compete with Paiste and Meinl head to head with this alloy?<br> | ||

| + | '''We recently received first hand accounts that both Sabian and Zildjian use "Weiland works" as their supplier for B8 blanks, the same foundry that Paiste uses!'''<br> | ||

| + | |||

| + | [https://www.cymbal.wiki/wiki/Alloys <b>Paiste wiki cymbal alloy analysis</b>]<br> | ||

| + | [https://en.wikipedia.org/wiki/Cymbal_alloys#Bell_bronze <b>Wikipedia Cymbal alloys</b>]<br> | ||

| + | [https://en.wikipedia.org/wiki/Rolling_(metalworking) <b>Cold rolling and hot rolling</b>]<br> | ||

| + | [https://en.wikipedia.org/wiki/Annealing_(materials_science) <b>Annealing</b>]<br> | ||

| + | [https://en.wikipedia.org/wiki/Tempering_(metallurgy) <b>Tempering</b>]<br> | ||

| + | |||

| + | The ads below were produced before Sabian existed and Meinl was minor player and had not entered the U.S. market ('79- '82), Paiste was Zildjian's only competition at the time. | ||

| + | <gallery> | ||

| + | File:Zildjian-cookie-cutter-ad.jpg|"while other cymbals are stamped out of sheet metal and quickly formed" | ||

| + | File:Zildjian-sheet-metal-ad.jpg|"stamped out of sheet metal" | ||

| + | </gallery> | ||

| + | |||

| + | ===Alloy analysis of several different cymbals brands and segues=== | ||

| + | [[File:Alloy-analysis-h2.jpg|1000px|]] | ||

==Notes and references== | ==Notes and references== | ||

| Line 179: | Line 229: | ||

-------------- | -------------- | ||

| − | Special thanks to Fritz Steger [https://www.drumhouse.com/ of Drumhouse.com]<br> | + | Special thanks to Fritz Steger for his eyewitness accounts and observations: [https://www.drumhouse.com/ of Drumhouse.com]<br> |

Return to the '''[[Paiste|Paiste Main Page]]<br> | Return to the '''[[Paiste|Paiste Main Page]]<br> | ||

Return to the '''[[Paiste Series|Paiste Series Portal]]<br> | Return to the '''[[Paiste Series|Paiste Series Portal]]<br> | ||

Return to the '''[[Paiste Cymbal Type|Paiste Type Portal]]<br> | Return to the '''[[Paiste Cymbal Type|Paiste Type Portal]]<br> | ||

Latest revision as of 17:21, 2 October 2023

Contents

- 1 B20 production (Formula 602, Modern essentials 602’s)

- 2 Continuous strip or band casting process

- 3 Twenty and Twenty Masters Collection production

- 4 B15 (Paiste Signature Sound Alloy)

- 5 B8 (2002 Alloy)

- 6 Swiss and German factories

- 7 A word about "cast" vs. "sheet bronze" cymbals:

- 8 Notes and references

B20 production (Formula 602, Modern essentials 602’s)

The processes described below apply to Paiste's current "top line" cymbals and some of their "midline" cymbals.

Paiste does not have a foundry, they have traditionally used an outside supplier to provide their alloys with the first production stage completed.

For the B20 alloy they are delivered to Paiste as circular “blanks”.

- The B20 “blanks” were supplied by Swissmetal from 1957 to 1994, they were originally called "Metallwerke Dornach AG".

- Metallwerke Dornach supplied B20 alloy for the Swiss mint, Swiss coins were made out of B20 bronze.

- Robert Paiste founded the Swiss factory across the lake from where Metallwerke Dornach was located by accident (Paiste had not used B20 alloy up to that point), little did he know they were the only foundry and mill that produced B20 bronze in all of Switzerland and possibly all of western Europe!

- Robert Paiste initially worked with Swissmetal and developed a process of rolling B20 thin enough for B20 cymbal production: Fritz Steger's explanation of the sourcing and development of Paiste's B20 alloy.

- The Formula 602 and Sound creation lines were discontinued around 1994 (or earlier) because Swissmetal stopped making B20 blanks, it is understood that Swissmetal went through substantial financial difficulties during this time, it’s assumed it wasn’t cost effective for them at that point as Paiste would have been a small customer.

- "Weilandworks" in Vöhringen Germany now supply all of Paiste's alloys but specifically; they supply the B20 blanks for the “classic 602’s” and "modern essentials 602’s".

There are advantages to using industrial foundries and mills: Production is on a much larger scale, they can produce several hundred blanks from one batch of alloy, the foundry also has the ability to keep incredibly tight tolerances on temperature control and mixing along with metallurgical analysis to ensure the alloy has the correct characteristics for reliable consistent cymbals making.

The production process at the foundry and mill: B20 bronze is produced by hot rolling [1] in multiple stages from a thick plank/ingot into a thin sheet slightly thicker than the heaviest cymbal thickness required (Wieland works may use the continuous casting process for B20 alloys, see below).

(The “hot rolling process” [1] forms the desired and stable crystalline structure that contributes to the more refined sound of Bell Bronze). B20 is a "two-phase" alloy: meaning some of the tin is not dissolved in the copper grains but exists between them, in its natural state it is very brittle, there is a large amount of work done to the material (heating/recrystallisation) to get it conditioned so it can be hammered and lathed without cracking.

After being rolled out to approximate size and thickness, flat blanks are cut to the specified size and delivered to Paiste. They are then reheated to "anneal" them (soften) and then quenched in water, a bell is then stamped in the blank.

In terms of shape at this stage, they are a raw, unworked cymbal blank, the cymbal looks like a giant bronze potato chip covered in oven crust.

After this process, the cymbal is cleaned of the scale, a hole is punched in the bell and the hammering process begins.

Hammering: Paiste has used the same production processes from at least the mid 50's or earlier (they got their first hammering machine in 1952) to the present on all thier top of the line Swiss and German produced cymbals.

An electro pneumatic hammer is operated manually by the cymbal-smith, he wears a mount with a spindle on his left knee that holds the cymbal, he uses his thigh to move the cymbal in and out from the hammer to position the blows, with his right foot he controls the power/depth of the hammer blows, with his hands he rotates the cymbal to evenly distribute the hammer marks.

Paiste has been using this technique and the same type of machines since at least the mid 50’s or earlier.

The next step is fine tuning: a different cymbal-smith now hammers the cymbal by hand to fine tune the shape and checks the bow with a ruler and on a steel flat table to make sure the edges are straight, he also checks the cymbal against a “master” for hammer pattern and shape of the bow.

- Paiste is the only company out of the “big four” (Paiste, Zildjian, Sabian and Meinl) that uses manual machine hammering to shape the curve or “bow” of all of their top line cymbals. they have used the same process since 1952.

- Meinl uses a computer controlled hammering machine to shape one line of their cymbals otherwise the majority are "spin formed" into shape (the exception are Meinl's Byzance Turkish made cymbals), all of their cymbal production is completely computer controlled and automated.

- Zildjian and Sabian use a 75 ton press to STAMP most of their cymbals to create the "bow" or shape of the cymbal (there are some exceptions).

Specification card: Each cymbal-smith has a “specification card” that travels with each model/size of cymbal, it tells him the exact weight, thickness and hammering pattern for that cymbal.

Lathing: Lathing does two things: brings the cymbal down to the desired thickness and creates the lathing grooves which refines the sound and defines the character of that cymbal line.

The cymbal-smith checks the thickness of the cymbal with a micrometer during this process, the thickness must be no more or less than 0.01mm.

Finishing: The edges are cleaned up and chamfered, a serial number is laser etched into the bottom. The cymbals then have their respective logo, model, size printed on them and a protective coating is applied (Paiste was the 1st. to do this with the 602 series in the 1960’s).

Quality control: Each cymbal is tested against a finished “Klangmuster” (master cymbal) for consistency, if it does not pass the cymbal is rejected and scraped.

Rhythm Magazine Paiste factory tour B8 production

Continuous strip or band casting process

Weilandworks uses the continuous strip or band casting process for producing B20 B15 and possibly B20 alloys it supplies to Paiste.

What is the difference between casting and continuous casting?

Basically, in Ingot casting, individual molds are filled with molten steel to produce bronze ingots whereas in Continuous casting, the molten alloy is solidified into a "semi finished" billet, or slab for subsequent hot or cold rolling in the finishing mills.

What is the advantage of continuous casting?

Continuous casting helps improve the quality of metal products by reducing impurities and variations in size and shape. This results in consistent and higher-quality products with fewer defects.

The continuous casting method offers a superior surface finish and virtually eliminates internal porosity and centerline shrinkage.

The majority of bronze castings are produced through the sand casting process. However, there are clear deficiencies in the this choice when compared to continuous casting.

What are the disadvantages of continuous casting?

It isn't economical to use this method with special metal alloys in small quantities

In conclusion, continuous casting offers several advantages, including high productivity, consistent quality, and cost-effectiveness.

Twenty and Twenty Masters Collection production

The original “Twenty” blanks were supplied from the Foundry of Murat Diril in Turkey along with pre-work done to the cymbals before they were shipped off to Switzerland for completion.

There were well publicized issues with the quality of the blanks and high rejection rate, so Turkish suppliers were changed before the current Twenty Custom/Twenty Masters series started.

The process with their new supplier according to Paiste: "They begin by being hammered and shaped in Turkey, then we send them to Switzerland where we do the finish hammering and lathing and all the other work that makes it a Paiste cymbal."

All the hammering is done by hand according to Erik Paiste: “Paiste emphasizes that every crucial stage of the production is completed by hand, from the initial casting to the lathing and hammering.”

B15 (Paiste Signature Sound Alloy)

Paiste's B15 (Signature Sound Alloy) blanks are supplied by the "Wieland works" in Vöhringen Germany. They were initially supplied by "Kovohutí Příbram" from the Czech republic but they had serious issues with cracking, once the production moved to Wieland, the issue was resolved. Fritz Steger describes the early production issues with B15

B15 like B20, goes through some of the same processes: initially hot rolled to about 60mm thickness then the last stage is cold rolled. Also, it is not tempered [4] like traditional B20 cymbals but is annealed [3].

Using this alloy allows for greater consistency between blanks compared to traditional B20 cymbal alloy, and is more inline with Paiste's B8 production methods.

Once they arrive at Paiste, they would have to heat the whole of the cymbal again to anneal it [3] and then press the in the bell.

After this process, the blank is allowed to cool for 24 hours. As a result of annealing, the material is now more pliable, tougher and ready for hammering.

Hammering: Same processes as B20.

Lathing: Same processes as B20 except Paiste developed a different shaped knife for a unique "flat groove" lathing pattern for the Signature series.

Finishing: Same processes as B20.

Quality control: Same processes as B20.

Early 90's factory tour with Nicko McBrain B15 Signature cymbal production tour

U.S. patent for "Signature alloy"

Paiste's description of the production process in the U.S. patent

"The material or special alloy for the inventive cymbal 1 can be processed, by way of example and not limitation, as hereinafter disclosed:

An alloy containing, for example, 14.7 percent by weight tin, 0.08 percent by weight phosphorus and 85.22 percent by weight copper is initially melted in an induction melting furnace.

The melt is delivered at a temperature of 1000° C. to 1200° C. into a heat retention or holding furnace of a strip or band casting installation. A strip or band is cast.

The cast strip or band has, for example, a width of 670 mm and a thickness of 18 mm. This strip or band cannot be coiled and is therefore cut into plates of approximately 3 to 4 meters length.

Such plates are now homogenized at 600° C. to 700° C. during about 10 to 25 hours.

Then the casting and oxidation skin is removed by means of a milling tool or cutter or equivalent structure. Thereafter the plates are initially only slightly cold rolled, i.e. by about 20 percent and then recrystallized at temperatures between 500° C. and 700° C.

This process cycle of cold rolling and recrystallization takes place until a final sheet or plate thickness of 1 to 2 mm is obtained. Then a final annealing is carried out at temperatures between 400° C. and 500° C.

The obtained grain size then should be between 0.003 and 0.015 mm. The hardness should lie between 150 250 kilopounds per square millimeter, depending on the strived for sound or tone character.

Now circular blanks or discs of, for example, 200 to 610 mm in diameter are cut out of this sheet or plate from which there is formed the aforedescribed cymbal 1.

The cymbal 1 shown by way of example in FIG. 1 and described with reference thereto can be fabricated as follows:

The dome or cup 11 is formed at the corresponding blank or disc heretofore described by pressing, die stamping, drawing or in any other suitable manner. The hole or aperture 111 is drilled into the zenith or apex of the dome or cup 11.

Further forming or shaping is carried out by hammering the cold material. The thus formed or shaped cymbal is superficially faced or surface finished, preferably by hand, and then provided with a suitable conservation or preservation layer or film."

B8 (2002 Alloy)

B8 alloy is very different compared to B20: it's softer, much more malleable, easier to work and doesn't require multiple heating stages before each rolling cycle to prepare it for hammering.

Paiste's B8 alloy blanks originally came from Metallwerke Dornach AG, aka: Swissmetal, the same source as their B20, they are now supplied by the "Wieland works".

Wieland produces cast ingots that are cooled and "cold rolled" [1] multiple times into thin sheets.

(Cold rolling operation actually increases the strength via "strain hardening" up to 20%, it also improves the surface finish and holds tighter tolerances).

The mill then cuts circular blanks out of the sheets and delivers them to Paiste. Once they arrive at Paiste, they would heat the center of the cymbal in order to press the in the bell.

For the china type cymbals they "form or spin" the shape of the bell into the unique cylindrical shape.

Hammering: Same processes as B20 & B15.

Lathing: Same processes as B20 & B15.

Finishing: Same processes as B20 & B15.

Quality control: Same processes as B20 & B15.

B8 production tour with Dave Lombardo

Swiss and German factories

The German factory was the 1st, to start production around 1947/48, in 1957 Robert Paiste moved to Nottwil Switzerland by himself and setup the Swiss factory. The German factory is the sole producer of gongs, and has been since opening.

Both factories made both levels of product except the German factory didn't make B20 cymbals or Giant beats.

Many 2002's were made in 70s and 80s at the German factory and the German factory also "finished" a small number of 602s during the preserial days (** see below).

The German factory made practically all the vintage Paiste lines: 2002 (up to 1986), 2000, 1000, 400, 200, Stambul '65, Stambul, 404, 505, Ludwig cymbals, Dixies, Supers, Stanoples, Zilkos, etc.

They still make all the lower lines and "OEM" cymbals, see video link below.

There is a notion among some that the Swiss versions are better quality... they are not, some German versions are usually a little heavier and a little darker sounding.

People are less familiar with German Paistes because the Swiss factory did most of the exporting, so the U.S. didn't get German 2002's or 404's or 505's.

The German Paistes were meant for the German market and probably certain countries in Central Europe, everyone else got Swiss cymbals.

(**) Correspondence with Paiste Switzerland:

"By reason of a distributed capacitance, we have some Formula 602's that have been finished in Germany at the end of the 1950's.

They were annealed and hammered in Switzerland and Paiste Germany has completed them. That’s the reason they have a stamp “made in Germany”.

Kind regards, Customer Service Department

Paiste Switzerland"

A word about "cast" vs. "sheet bronze" cymbals:

Zildjian and Sabian (mainly Zildjian) have for many years used these terms in their marketing and advertising, they've alluded to in the past about B8 (and possibly B20 602's as well) "sheet bronze", "cookie cutter" cymbals being "stamped and formed" and inferior in both sound and quality (see advertisements below).

There are many misconceptions created by these statements: both alloys are "cast" at some point, B20 is delivered to Zildjian and Sabian as cast ingots from their in house foundry, they then heat and "hot roll/cross roll"

(see link below) the ingots to the general size and thickness, they must be reheated after every rolling stage (Paiste's B20 supplier uses this same process), they are also tempered/annealed and quenched (see link below) during this time and before being stamped into shape (for most of thier lines) and lathing.

The reason for this is the B20 alloy is very brittle (the tin doesn't completely mix with the copper at a microscopic level, in the B8 alloy it does), there is a large amount of work done (heating, reheating quenching) to the material just to get it conditioned so it can be hammered and lathed without cracking!

The B8 alloy is very different, it's much more malleable and workable, the foundry (Weilandworks) most likely pours out long square ingot bars (the casting part), it is then cooled and "cold rolled" multiple times (see link below) into long thin sheets (hence Zildjian's term "sheet bronze"), they then cut circular discs out of the sheet and deliver them to Paiste. Cold rolling operation actually increases the strength via "strain hardening" up to 20%, it also improves the surface finish and holds tighter tolerances.

To summarize:

B8 production techniques and the alloy itself does not make it inferior for cymbal making, it's just different, it's inherently easier to work with, its' more consistent batch to batch and doesn't suffer the higher rejection/defect rate that B20 does, this means B8 cymbals are less expensive to produce, not inferior quality. Paiste figured this out in the early/mid 60's and has mastered the production techniques and sound qualities of this alloy.

It's also telling that neither Zildjian or Sabian have attempted to produce a top level B8 cymbal (Meinl has for decades), could it be that Zildjian and Sabian can't or don't want to compete with Paiste and Meinl head to head with this alloy?

We recently received first hand accounts that both Sabian and Zildjian use "Weiland works" as their supplier for B8 blanks, the same foundry that Paiste uses!

Paiste wiki cymbal alloy analysis

Wikipedia Cymbal alloys

Cold rolling and hot rolling

Annealing

Tempering

The ads below were produced before Sabian existed and Meinl was minor player and had not entered the U.S. market ('79- '82), Paiste was Zildjian's only competition at the time.

Alloy analysis of several different cymbals brands and segues

Notes and references

Rolling

[1] Rolling is a metal forming process in which metal stock is passed through one or more pairs of rolls to reduce the thickness, to make the thickness uniform, and/or to impart a desired mechanical property.

The concept is similar to the rolling of dough. Rolling is classified according to the temperature of the metal rolled:

If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling.

If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling.

Cross rolling

[2] Cross rolling is a way of reducing the directional dependency of different properties of the rolled plate.

Cross rolling is normally done by changing the rolling direction by 90° about the normal direction.

Changes in residual stress distribution cross rolling leads to rolled product of comparatively uniform mechanical properties in all directions.

Annealing

[3] Annealing is a heat treatment that alters the physical and sometimes chemical properties of a material to increase its ductility and reduce its hardness and makes it more workable.

It involves heating a material above its recrystallization temperature, maintaining a suitable temperature for an appropriate amount of time and then cooled.

Bronze can be either cooled slowly in air, or quickly by quenching in water. In this fashion, the metal is softened and prepared for further work such as hammering, shaping, stamping, or forming.

Tempering

[4] Tempering is a process of heat treating, it is done to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air.

The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product.

Special thanks to Fritz Steger for his eyewitness accounts and observations: of Drumhouse.com

Return to the Paiste Main Page

Return to the Paiste Series Portal

Return to the Paiste Type Portal